Before moving further with the topic, you must know what a commercial kitchen hood system actually is and how it is that important for your kitchen. We will also explore the basic commercial kitchen hood code requirements and discuss how to ensure compliance with these regulations.

What is a Commercial Kitchen Hood System?

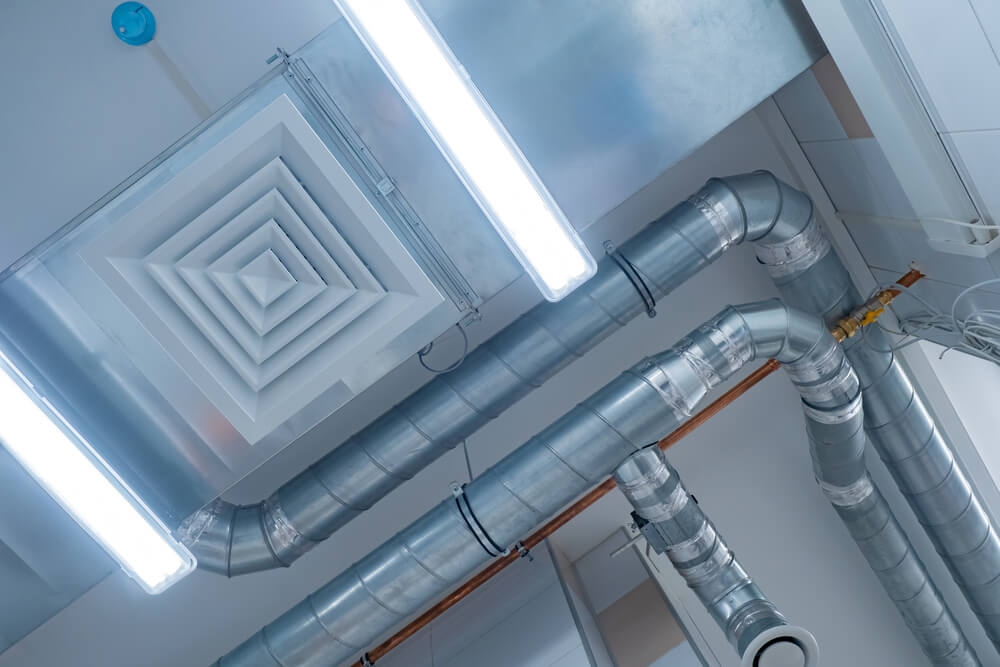

A commercial kitchen hood system, also known as a range or exhaust hood, is a vital device installed above cooking appliances to ventilate the kitchen and maintain air quality. Its primary function is to remove smoke, grease, and harmful particles from the air, ensuring a clean and safe working environment for kitchen staff. By pulling in the contaminated air and expelling it through ductwork to the outside, kitchen hoods prevent the buildup of harmful gases and grease. Equipped with a make-up air system, they ensure that any air filtered out is replaced, keeping the kitchen well-ventilated and safe for operation.

Types of Kitchen Hoods

There are actually two types of commercial kitchen hoods, and these types are known as Type I and Type II hoods. These hoods are recognized by the types of materials they filter out of the kitchen’s environment. Below are the characteristics of both of these hoods.

- Type I Hoods: Type I hoods are also recognized as grease hoods, these are designed in such a way that they remove heat, smoke, and any other harmful airborne grease that is present inside the kitchen. Type I hoods are often found over appliances such as fryers, broilers, grills, and ovens.

- Type II Hoods: Type II hoods are also called condensate hoods, they help in removing steam, vapor, and other moisture from the air of your kitchen. Some of these hoods even remove odors as well. They are also found on top of coffee machines, commercial dishwashers, and some particular pizza ovens. Furthermore, these types of hoods often lack a grease filter, so they should not be used instead of Type I hoods.

Ducted vs Ventilated Kitchen Hoods

Commercial Kitchen Hood Code Requirements

Commercial kitchen hood systems must comply with specific code requirements to ensure safety, fire prevention, and proper ventilation. Here are some key code requirements for commercial kitchen hood systems in the U.S., mainly based on the International Mechanical Code (IMC), NFPA 96 (Standard for Ventilation Control and Fire Protection of Commercial Cooking Operations), and local building codes:

1. Types of Hood Systems

- Type I Hoods: Required for kitchens with cooking equipment that produces grease and smoke, such as fryers, grills, and ovens.

- Type II Hoods: Installed for heat and moisture-producing equipment like dishwashers or steamers. These hoods are not for grease-producing equipment.

2. Materials

- Hoods must be made of non-combustible materials like stainless steel.

- The minimum thickness for stainless steel hoods is 0.0466 inches.

3. Exhaust and Ventilation

- Exhaust systems must move a minimum airflow based on the type of cooking equipment and the heat or grease generated.

- Make-up air (replacement air) must be provided to ensure adequate ventilation without negative pressure in the kitchen.

- Exhaust fans must be interlocked with the cooking equipment, meaning they should automatically activate when the cooking equipment is turned on.

4. Clearance Requirements

- Minimum clearance from the hood to combustible materials must be 18 inches unless reduced by approved materials or enclosures.

- For Type I hoods, the distance from the cooking surface to the bottom edge of the hood should generally be 24-30 inches.

5. Fire Suppression Systems

- Type I hoods are required to have an automatic fire suppression system. This could be a wet chemical system or other approved systems as outlined by NFPA 96.

- Manual activation of the fire suppression system must also be installed in a readily accessible location.

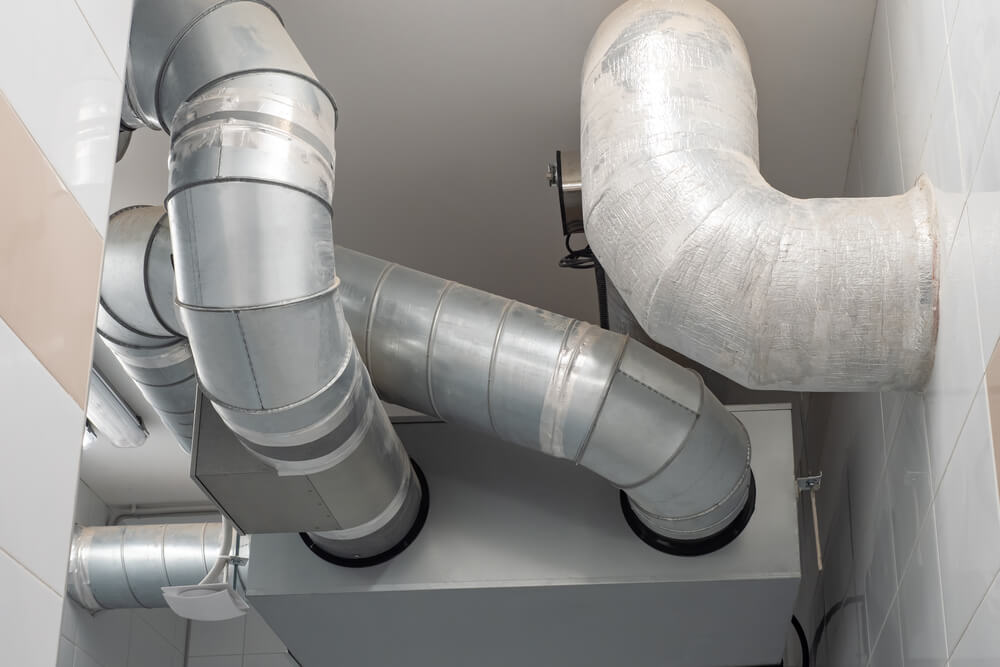

6. Ducts

- All exhaust ducts must be constructed of stainless steel or other non-combustible materials, with proper slope for grease drainage.

- Grease ducts must be air-tight and sloped towards a grease collection device.

- Ducts should terminate above the roofline and be at least 10 feet away from air intakes or building openings.

7. Grease Filters

- Hoods must include grease filters that are removable, washable, and constructed of non-combustible materials.

- Grease filters must be installed at an angle of 45 degrees or more to allow grease to drain into a grease tray.

8. Inspection and Maintenance

- Regular cleaning and inspection of hoods, ducts, and filters are mandatory. This includes cleaning schedules based on the amount of cooking:

- High-volume cooking: every 3 months.

- Moderate-volume cooking: every 6 months.

- Low-volume cooking: every 12 months.

9. Fan Requirements

- Fans must be UL-listed for grease-laden air and must shut off automatically if the fire suppression system activates.

- Exhaust fans should be designed to operate continuously during cooking operations.

10. Lighting

- Hoods must have sufficient lighting, with fixtures protected by shatterproof covers, per IMC requirements.

11. NFPA 96 Requirements

- NFPA 96 also requires certain equipment like spark arrestor filters for solid-fuel cooking equipment.

- Regular testing and certification of fire suppression systems must be performed according to NFPA guidelines.

12. Local Codes

- It’s important to comply with local fire and building codes in addition to national standards. Local authorities might have additional requirements regarding hood installation and fire safety.

Commercial Kitchen Hood Cleaning Code Requirements

Cleaning and maintaining commercial kitchen hoods is crucial for fire safety and ensuring the efficient operation of the ventilation system. The following are the key code requirements and best practices for commercial kitchen hood cleaning, primarily based on NFPA 96 (Standard for Ventilation Control and Fire Protection of Commercial Cooking Operations) and the International Mechanical Code (IMC):

1. Frequency of Cleaning

- High-Volume Cooking Operations: Hoods, ducts, and fans must be cleaned every 3 months.

- Moderate-Volume Cooking Operations: Cleaning should be done every 6 months.

- Low-Volume Cooking Operations: Cleaning should occur every 12 months.

- These intervals might be adjusted based on the type and volume of cooking, as well as local fire code requirements.

2. Certified Cleaners

- Only certified and qualified professionals should perform the cleaning of commercial kitchen hoods. These professionals must have the necessary training and certifications as specified by NFPA 96 and other relevant standards.

3. Cleaning Procedures

- Hoods: Must be thoroughly cleaned to remove all grease and residues. The cleaning process typically involves scrubbing, washing, and sanitizing the hood’s surfaces.

- Ductwork: Should be inspected and cleaned to ensure no grease accumulation. Ducts must be cleaned in accordance with the same schedule as the hoods, or more frequently if needed.

- Fans and Filters: Fans and filters should also be cleaned regularly to maintain their efficiency and ensure proper airflow.

4. Documentation

- Cleaning Records: Maintain detailed records of all cleaning activities, including dates, service providers, and descriptions of work performed. This documentation should be readily available for inspection by fire marshals or other authorities.

5. Inspection and Maintenance

- Regular Inspections: Conduct routine inspections of the hood system to check for grease buildup, operational issues, and compliance with cleaning schedules.

- Maintenance: Perform regular maintenance on the hood system to ensure it remains in good working order and that all components, including fans and filters, are functioning correctly.

6. Fire Safety Considerations

- Fire Suppression Systems: Ensure that the fire suppression system is operational and has been tested in accordance with NFPA 96 requirements. The system should be serviced and tested by qualified technicians.

- Grease Traps: Clean and maintain grease traps and other grease collection devices to prevent overflow and potential fire hazards.

7. Compliance with Local Codes

- Local Regulations: In addition to national standards, adhere to local fire codes and building regulations, which may have additional requirements or more stringent cleaning schedules.

Adhering to these code requirements and best practices ensures that commercial kitchen hood systems are effectively maintained, reducing the risk of fire and promoting a safe and efficient kitchen environment.

Commercial Kitchen Hood Electrical Requirements

The electrical requirements for commercial kitchen hoods are crucial for ensuring safe and efficient operation. These requirements are outlined in various codes and standards, including the National Electrical Code (NEC), NFPA 96, and local building codes. Here’s a summary of key electrical requirements for commercial kitchen hoods:

1. Power Supply

- Dedicated Circuit: Kitchen hoods must be connected to a dedicated electrical circuit to prevent overloading and ensure reliable operation. The circuit should not be shared with other equipment.

- Voltage and Amperage: Ensure that the power supply meets the voltage and amperage specifications of the hood system as indicated by the manufacturer.

2. Electrical Connections

- Wiring: Use wiring that is rated for high-temperature and moisture-resistant environments, as kitchen hoods are exposed to heat and potential grease accumulation.

- Connections: Electrical connections should be securely made and protected from moisture and grease. Use junction boxes and conduit to ensure connections are safely enclosed.

3. Control Systems

- Interlocking: The hood’s fan should be interlocked with the cooking equipment so that the fan activates when the equipment is turned on. This helps to ensure proper ventilation and safety.

- Controls: Install controls for the fan and lighting in a location that is easily accessible and clearly labeled. Ensure that control systems comply with electrical codes and manufacturer specifications.

4. Disconnect Switch

- Accessibility: Install a disconnect switch for the hood’s electrical system that is easily accessible and clearly marked. This switch allows for quick disconnection in case of maintenance or emergency situations.

- Location: The disconnect switch should be located within sight of the hood or in an accessible location close by, as per NEC requirements.

5. Grounding and Bonding

- Grounding: Properly ground the hood system to prevent electrical shock and ensure safety. All metal parts of the hood and its components must be grounded.

- Bonding: Ensure that the hood system is bonded to the building’s electrical system to prevent static electricity build-up and reduce the risk of electrical faults.

6. Electrical Components

- Fans and Motors: Electrical fans and motors must be UL-listed or approved for use in grease-laden environments. Ensure they are regularly inspected and maintained.

- Lighting: Install lighting fixtures that are rated for use in commercial kitchens, with shatterproof covers to protect against damage from heat or moisture.

7. Code Compliance

- NEC Compliance: Adhere to the National Electrical Code (NEC) for all electrical installations, including wiring methods, circuit protection, and equipment grounding.

- Local Codes: Follow local building codes and regulations, which may have additional or more stringent electrical requirements for commercial kitchen hoods.

8. Maintenance and Inspection

- Regular Inspections: Schedule regular inspections of the electrical components of the hood system to identify and address any issues before they become major problems.

- Qualified Personnel: Ensure that all electrical work is performed by a licensed electrician or qualified technician to comply with safety standards and regulations.

Conclusion

In conclusion, adhering to the regulations and requirements for commercial kitchen hoods is essential for maintaining a safe, efficient, and compliant kitchen environment. By following established codes such as NFPA 96 and the International Mechanical Code, and ensuring proper installation, maintenance, and cleaning practices, kitchen operators can mitigate fire risks, improve air quality, and enhance overall operational efficiency. Regular inspections, adherence to electrical and safety standards, and the use of certified professionals are key to ensuring that commercial kitchen hood systems perform optimally and meet all regulatory requirements. Compliance not only protects the health and safety of kitchen staff but also helps in maintaining a smooth and effective kitchen operation.

FAQs

What are the specifications for a commercial kitchen hood?

Commercial kitchen hoods must meet local building and fire code requirements. General specifications include:

- Type 1 hoods: Required for cooking equipment that produces grease or smoke (e.g., fryers, grills).

- Type 2 hoods: Used for heat and moisture (e.g., ovens, dishwashers).

- Material: Typically 18-gauge stainless steel or thicker.

- Exhaust rate: Depends on the equipment but generally ranges from 150–600 CFM per linear foot of hood.

- Grease filters: Must be UL 1046 rated and installed at a tilt for proper drainage.

- Fire suppression system: Required for Type 1 hoods.

- Make-up air: Must be supplied to replace exhausted air.

What is the required height of a commercial kitchen hood from the floor?

The bottom of the hood should typically be:

- 6 feet 6 inches to 7 feet above the finished floor (78–84 inches).

- At least 18 inches above the cooking surface for most appliances.

Always follow manufacturer guidelines and local code requirements, as these can vary by jurisdiction.