A walk-in cooler is a room-like refrigerator and freezer where you can store big chunks of food for preservation purposes. Usually, walk-in coolers are made with metals alongside panels of foam insulation. It is slightly different than a regular refrigerator because many different panels configurations and cam options are available in it which in the case of the refrigerator are unthinkable. Here is your list of instructions for installing a walk in cooler.

Kitchen services provide you a complete guide for the selection of your required walk-in cooler.

Types of Walk-In Coolers

There are two basic types of walk-in coolers.

- Prefabricated Walk-In Cooler

- Built-In Walk-In Cooler

If you are familiar with your requirements and have ordered a commercial walk-in cooler using our guide. Then it’s time for you to learn about its installation and if you can do it yourself or not.

Walk-In Coolers Installation | DIY

Walk-in cooler installation can seem like a daunting task, but don’t let it be! Walk-in cooler installation is a very easy process. The following article will explain some simple things to keep in mind before you begin the install. Planning is critical to success either you are a business owner or just a worker in a firm. There are many reasons new walk-in installations fail, but one of the most common is not planning or preparing properly. As Benjamin Franklin so famously said, “By failing to prepare, you are preparing to fail.” Just as you formulate a solid plan for your business, the same should be true when you are ready to install a new walk-in cooler or freezer in your home or resort. Hopefully, you will find the following steps helpful in developing your plan of action for the commercial walk-in cooler installation.

Installing a walk-in cooler is one tricky job. There are proper technicians who have expertise in installing a commercial walk-in cooler. DIY is out of the question when it comes to a commercial walk-in cooler because it is one massive piece of equipment that is loaded with highly engineered components and you as a layman would destroy the components.

This job requires a properly trained technician. So make sure you have fixed your appointment with a commercial walk-in cooler installation expert. If you are looking for walk in cooler installation service providers in Los Angeles and surrounding areas.

Call Kitchen Services for all installation and maintenance (323) 310-2010

Inspect your commercial walk-in cooler just when it delivers – While unboxing the panels of a walk-in cooler, make sure that each panel has been delivered to you safely and nothing is damaged. If you find anything damaged and non-relative to your particular walk-in cooler just dial the claim number provided by the services. Usually, shipping is one safe way of sending machinery to far destinations but sometimes equipment gets a bit damaged during travel. So, you must inspect all the panels and components of your commercial walk-in cooler.

Check all panels and handle them – Before shipment, the panels go through quality check control individually so that you won’t have to go through the trouble of returning one. Anyways, once you unbox the material put the panels on a steady surface to avoid dents and damages. Use sufficient manpower for handling and dropping purposes.

Prepare your site for installation – Make sure that the place you have chosen for installation purposes is okay and doesn’t have any moisture on it. Mark the crucial points with some chalk or marker for good measurement.

Take measures for floor panels – Once the installation site is cleared now you need to mark down the lines for floor panels. The lines will help you with the exact installation.

Measures for floorless installation – Marking is also necessary for wall purposes however if the surface is dry that is more preferable for a floorless walk-in cooler. Make sure that you place the panels on the exact lining that you draw.

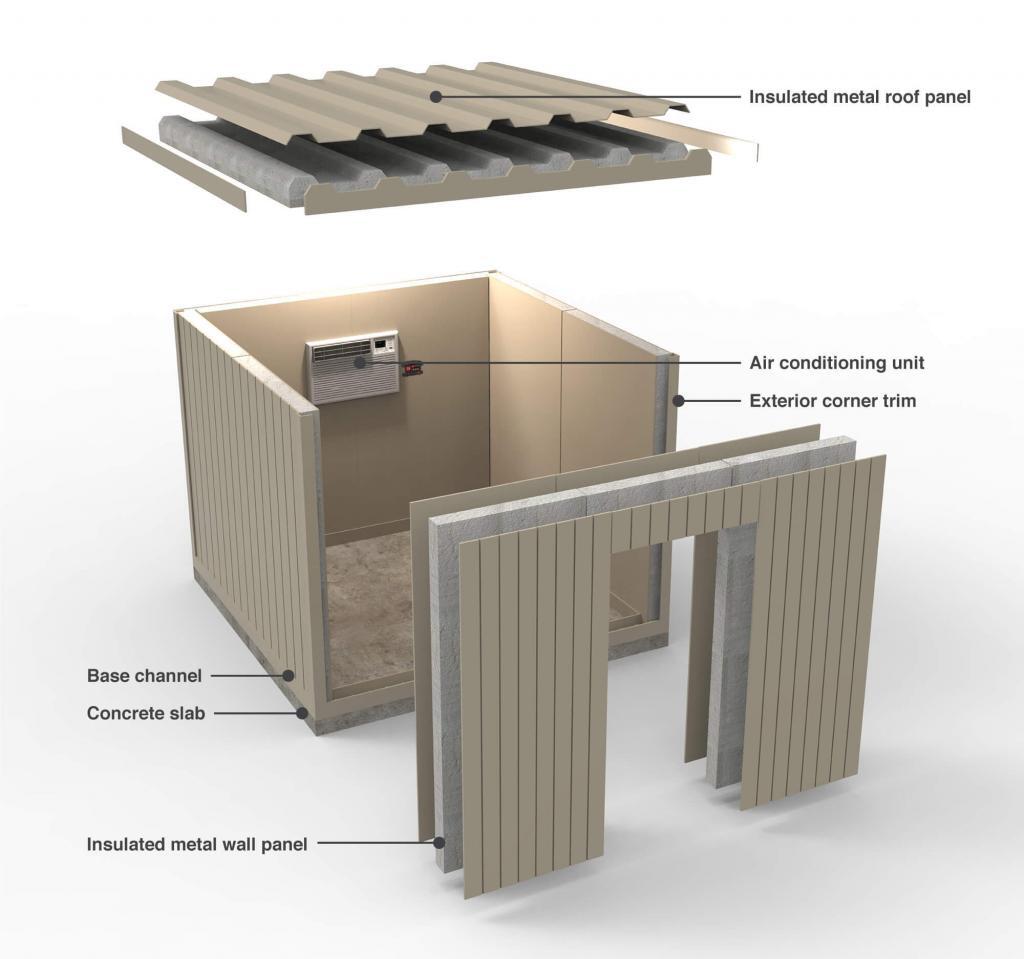

Wall assembly for installation – Follow the draw lines and select a rear corner panel, place it even with the outside of the base, and partially lock it into position. Select a wall panel on either side of the corner, firmly lock these panels to the corner. Once the structure is stabled on exact marks then it’s time to completely lock the panels so it may not loosen up with time.

Measures for indoor installation – For a ceiling over 16 ft. long, a suspended support system will be supplied.

Supports should be installed as per the engineering drawing supplied by the factory.

Measures for outdoor installation – Make sure the material of your walk-in cooler is highly reliable if that’s for outdoor purposes. A rainproof cap is recommended for safety purposes. The outdoor rainproof membrane is a 40-mill polyester fabric.

Rain roof installation instructions – Make sure that the material quality can withstand the heavy rainfall, however, we don’t recommend an outdoor walk-in cooler if you are in a tropical rainy area. Place vinyl roofing material, with flaps underneath, on top of walk-in across narrow end. Allow 6″ of vinyl to lap over each of the three sides. Carefully unroll vinyl material until vinyl flap falls into position.

Above mentioned steps are crucial for the successful installation of a commercial walk-in cooler. DIY is not an option with a commercial walk-in cooler. If you want to install your walk-in cooler, then this guide covers all the points that are mandatory for installation purposes.

If you have any concerns or questions at all, be sure to speak with your refrigeration tech or your walk-in cooler/freezer manufacturer. Asking questions can save you a bundle, so never hesitate to ask and let us know in the comment section about your experience.

Walk in cooler installation cost?

Walk in coolers can either be a room-sized which is a self-contained unit that can be as small as ten square feet or as big as a whole building, a walk-in cooler can be used in an array of commercial settings and for many different reasons. It can also be used in order to store different sorts of ingredients in any restaurant or even a bakery, but just as easily as storage for huge quantities of meat and dairy, and much more. It is commonly not something that is installed in a home, as well as it often requires upgrades to the structure, electrical services, ductwork, and much more.

The broad variety of many sizing options would make a huge price that is difficult to provide, even though experts always say that a walk-in unit may range from as little as $1,000 to upwards of $10,000, or even more. All the factors that may affect pricing may include the size of the cooled space, the number of updates that are needed to the electrical system as well as the hardware which may also include the potential for heavy-duty wiring, more breakers, and even new transformers, plumbing upgrades, and the layout of the building in which the walk-in cooler is installed. Any walk-in cooler installation that is 10 square feet can either be used for personal or even for commercial purposes.

The upside to a new walk-in freezer would might be that you are able to save a lot of your money in order to store any meat, specimen samples as well as many other items because of the reason that they can be stored for a very long time so it obviously does save you money and by not having to go back and buy any more of those things over and over again. The monthly costs are usually calculated using the national average cost per kilowatt-hour and then multiplied by the hours used in a year and divided by twelve. But not to forget these are sample averages and not accurate.

Proper Installation & Construction Is Pivotal

You have to keep this thing in mind that any of your walk-in freezers and coolers must be properly built and installed so that it can keep energy costs under your control. All of these builders that are experts in this field and know its worth would definitely know even the little details regarding how to construct and install a walk-in just so it runs effectively and well into your establishment’s successful run. This primary installation is very important for the purpose of cost effectiveness as well as stability. You will see later in this article that even the location of your walk in unit in your organization will influence energy efficiency that can save or ruin your budget.

Precise Insulation Shields Against Climbing Costs

The proper insulation starting from the floor to ceiling, as well as along the doors, should be the main trait for any highly constructed walk-in freezer and cooler. The whole purpose of any of your walk-in would be to keep the heat out and the cool in this purpose would only be achieved if you construct the unit to survive the outside heat transfer from the ambient temperature which is surrounding the walk-in. Even though the proper levels of insulation are always set by the Energy Independence and Security Act (EISA) and being informed and concerned about all these requirements is very important while you are shopping for and ultimately installing a walk-in freezer or cooler.

In terms of cost the location matters in more than one ways

It depends on where your operation is actually located, any of your walk-in units may have to work a lot harder so that it can regulate the internal temperature in order to keep energy costs at a very affordable level. This can be true for both hot and cold locations, which each require different processes to maintain proper temperature levels.

More certain than geographic location, the real placement of your walk-in that is within your institution can affect how much energy it actually uses. Any walk-in freezer or cooler that is situated next to any hot stove or even in direct sunlight would need more energy so that it can cool itself down in order to maintain its balance as more energy usage equals a higher energy bill that would cost you a lot more. Always keep this thing in your mind that you definitely have to take this into consideration while you are designing and building your food storage area, as it could prove difficult to move once it gets installed.

How Often the Walk-In Freezer Is Opened & Closed

Same as with any of your domestic refrigerator, the more it gets opened and even kept open the more energy the unit will use. In case your food service operation observes that a lot of people are frequently entering and leaving your walk-in freezer or cooler then obviously the outside temperature will start to ooze into the interior of the walk in unit, in this case, your walk-in cooler will have to work a lot more hard so that it can maintain and stabilize the temperature and keep your food safe. This might be unavoidable in many busy food service operations, but you have to be sure that all of your employees and other staff members are well aware that your energy bill could likely take a hit from the extreme opening and closing of the walk in unit door.

One of the best ways to avoid this is the vinyl stripping on walk-in doors as it is considered as a strategic way that can keep the cold air inside of the unit where it actually belongs.

Other considerations

- Always remember that the price of your walk-in unit will never reflect the need for permits. Some areas may require a lot of permits, which may include those from both buildings as well as health departments.

- It can be possible that you can save on the cost of a walk-in cooler installation just by choosing to install outdoors and give up on the expense for any kind of structural updates. Though there always will be a need to have a concrete slab present or even installed afterward, also the whole structure would definitely need protection from rain, winter weather, and any sort of harsh conditions.

- The size and power of your refrigeration system will also have an influence on the cost, with even more powerful or higher horsepower systems they may require a large outlay and even more in terms of all the power requirements.

- All the extra costs may come from the addition of the remote systems that will allow heat to be released outside of your building, all the side-mounted systems that remain low to the ceiling, saddle mount systems and even more.

- Any kind of the upgrades to the door of your walk-in unit may also increase the cost of the whole system, as well as an automatic door closer may also help in order to keep the air temperature regulated, but keep in mind that it also comes at a premium price.

- Delivery is also one of the main factors that you must always consider, whether the unit is turnkey or it needs to be constructed, all the number of components would make delivery a major project and one that should be managed by the individual or firm handling the actual installation.

- Last but not the least, selecting the floor in which your walk-in has to be installed can also be one of the factors that would help in order to keep your budget, cost as well as maintenance down over the long term. Not to forget that sanitizing the chosen flooring is a very important task that you must follow before installation.

Conclusion

It totally depends on the size, a traditional walk-in cooler might cost between $6,000 and $10,000. In addition to this upfront cost, you might also need to be concerned about all the operating costs that might be energy or even the service, which usually involves a specially trained technician. As we know that these appliances use a lot of energy as they operate around the clock in order to keep perishable products cold and fresh.

Typical commercial refrigerators may consume up to 17,000 kilowatt-hours of electricity where as large commercial freezers may consume up to 38,000 kilowatt-hours, which may result in high energy bills. It is likely worth investing in a walk-in cooler if your kitchen’s cold storage requirements or production capacity exceeds a reach-ins capabilities. Additionally, a walk-in could greatly improve your kitchen’s efficiency and organization.

Can you convert a walk in cooler to a freezer?

Cold storage solutions require a lot of engineering and careful design consideration. It is not advised that you convert walk-in coolers into walk-in freezers; however, it is possible to convert walk-in freezers into walk-in coolers

How much power does a walk in freezer require?

The annual power consumption of a walk-in freezer, if it were to be plugged in 24 hours a day, 365 days a year, would be around 700 kWh. One kWh is referred to as 1 unit of electricity, so a walk-in freezer can be expected to use 700 units of electricity annually.

What is the difference between a walk-in cooler and a walk-in freezer?

The more noticeable difference between cooler and freezers is the different working temperatures. Coolers work above 1˚ C (34˚F), while freezers work below 0˚C (32˚F). The different working temperatures require different insulating thickness for walls and ceilings, floor insulation, and floor warming