A backdraft damper helps to block the outside air from coming into your kitchen. In case the range hood has no backdraft, the damper is switched off for any purpose, it will still allow air into your kitchen, similar to an opened window. This might boost your utility bills during the months in which you let your heaters on as well. It usually acts just like a vent, opens when it is required, and closed when the range hood is not in use.

Why You Should Install Range Hood Backdraft Damper?

This is totally up to your choice if you want to install one that is dependent upon several factors. If you happen to live in an area that is very cold chances are that you would see many advantages from installing one in your commercial kitchen. The same is the case if you live in an area that is extremely hot and humid. If by chance you live in an area with a comparatively modest climate, an area where you do not run air conditioning or heating very often, you are likely to see less advantage in Installing one of these.

Dampers are used to control:

- Inward flow at intakes

- Outward flow through exhausts

- Air temperature and humidity by managing how stale or conditioned air mixes with external air

Damper Construction and Types

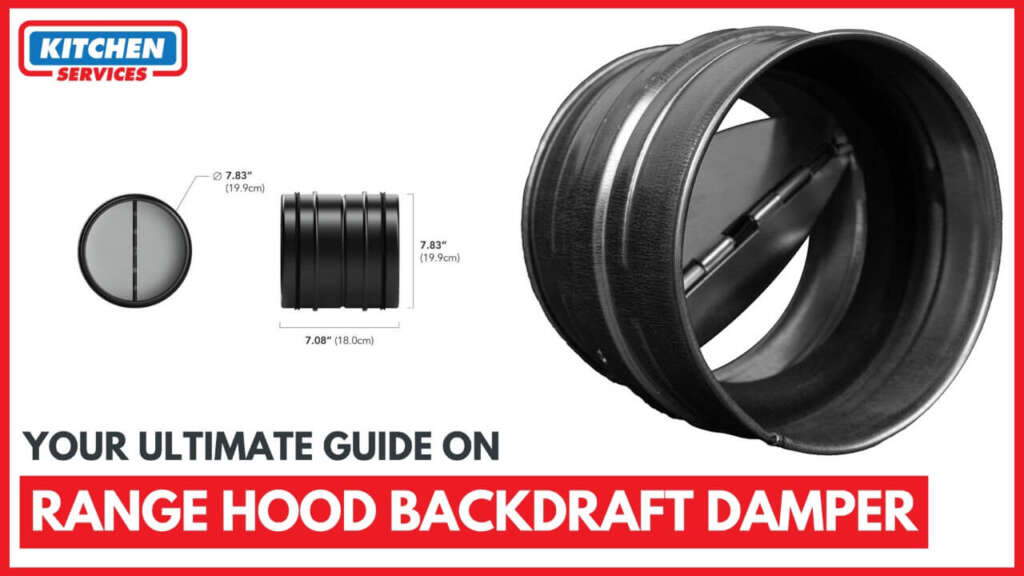

Dampers usually are made up of a frame with one or even more blades that are adjustable as well. You may also see some ‘bladeless’ dampers if you happen to survey the market. These frames can be in many shapes such as rectangular, square, oval, or round, it depends on the different shapes of ducts and openings that are already there in your commercial kitchen. Usually rectangular and square frames have at least four elements that are the top and bottom frame members and the side members that are called jambs. Whereas round or cylindrical frames are called sleeves.

As said earlier, these dampers have one or more damper blades, and each blade can change its angle and position to control the flow of air through the damper as required. When it is fully opened, blades will allow the maximum amount of air to flow through the damper. When it is fully closed, they will form a tight seal with the adjacent blade or with the frame, which would also restrict the airflow. Each blade changes its angle by moving around the axle on which it is mounted.

Dampers are classified based on application and actuator mechanism.

Dampers Based on Application

Backdraft dampers:

They are Meant to channel unidirectional airflow passing which means air flows in a single direction only from ducts and vents, they also prevent the air from flowing in the opposite direction. They are mostly used for bathroom fans and range hoods.

Balancing dampers:

These dampers are meant to level out imbalances in air pressure that is caused in between connected rooms in buildings that have centralized ventilation.

Control dampers:

These kinds are meant to actively regulate airflow through ducts and vents in ventilation systems. These dampers are often driven by manual, pneumatic, or electric mechanisms.

Safety dampers:

They are designed uniquely. They tend to shut off in case of fire and smoke. These are considered the safety devices that need to be certified by safety certification bodies such as UL.

Dampers Based on Actuator Mechanism

Manual dampers

As the name suggests these dampers open and close manually through a control lever or a chain. These kinds of dampers are commonly used as balancing dampers because they need to be adjusted very infrequently. These kinds of dampers are not suitable for use as backdraft dampers that need regular changes in blade position.

Gravity dampers

These dampers depend on gravity and air pressure to open or close. They are often used as backdraft dampers; they tend to open when air flows in one direction and close when there is no airflow or when the flow direction is reversed in any case. The other thing that needs to be considered is that they are often not as air-tight as spring dampers. This usually means that not only can they let in cold air, but they can let in insects and dust as well.

Spring dampers

Very much the same as gravity dampers, these generally depend on air pressure to open the damper but unlike gravity dampers, they use spring tension instead of gravity to drive the closing action. Butterfly dampers often have springs and are commonly used as backdraft dampers.

Electric dampers

An electrical damper is controlled by electric motors to open and close. They are very popular as control dampers in HVAC systems but are occasionally used as backdraft dampers too. Both gravity dampers and spring dampers are often integrated into wall and roof vent caps. Wall shutters are generally spring or gravity-type dampers. Dampers can also be driven pneumatically, but these are usually only used with large, centralized HVAC systems. Pneumatic actuators are becoming less popular due to their need for frequent maintenance and part replacement.

How to Choose the Right Backdraft Damper for Your Home

Here are the seven key factors to consider while you are choosing a backdraft damper for your needs:

Function:

Apart from their main function that preventing backdraft, there are many other functional requirements, such as temperature insulation, noise reduction, or insect deterrence.

Size and shape:

Do you need to observe exactly the dimensions and shape requirements for the damper? Well, This depends on the ductwork or opening where the damper needs to be installed and fitted.

Maximum pressure:

Every damper model is rated to a certain maximum pressure, beyond that pressure level it may not work perfectly as it should and it might also get damaged. Air pressure for dampers is usually expressed in ‘inches of water gauge’ which can be measured with a manometer, you will have to take readings at the point in the ductwork where the damper is to be fitted.

Maximum pressure should be measured while all upstream appliances connected to that duct, like exhaust fans or range hoods, are running.

Duct velocity:

Always remember that every damper is rated to a particular maximum airflow velocity, generally expressed in ‘feet per minute (FPM). Dampers may not function properly or may get damaged if the airflow velocity surpasses their maximum rated limit.

Duct velocity is calculated by the formula,

Duct velocity = 4005 x √(dynamic pressure)

Alternatively, if your damper has just one blower upstream, simply find out the blower’s manufacturer-specified output, expressed in ‘cubic feet per minute (CFM), and divide this by the duct’s cross-sectional area.

Duct velocity = Blower airflow / Duct cross-sectional area

For instance, if your range hood fan rated 160 CFM is ducting through an 8-inch circular tube, the typical velocity you can expect is:

Duct velocity = 160 / (πr2)

= 160 / (3.14 x (0.33)2)

= 160 / 0.342

= 467.84 FPM

“πr2” is the formula for the cross-sectional area of the circular tube. The 8-inch diameter of the tube is first converted to feet (0.66 feet) and then divided in half to get the tube’s radius of 0.33 feet.

Pressure drops:

Air flowing through ducting has a high chance of experiencing a drop in static pressure when it comes across any resistance, such as with a damper or other object. Any upstream blowers will have to work even harder to defeat this resistance, so excessive pressure drops can lead to higher energy utilization and may damage fans or shorten fan life.

Every damper tends to cause some amount of pressure drop, which is little no doubt. If you have blowers that are running a lot of the time, such as those in HVAC systems, choosing a backdraft damper that causes the least pressure drop can result in significant energy savings in the long run.

Leakage:

Keep in mind that dampers are not airtight, even if their blades are fully closed. Air that leaks through a closed damper is its ‘leakage’. Large amounts of leakage can cause challenges for the fans to work even harder, and also lead to temperature loss to the outside environment. Both of these factors will lead to poor energy productivity. Not only do the air leaks waste energy, but they will also create an uncomfortable cold draft.

Material:

Dampers for domestic applications are generally made of metal or plastic. Plastic is lighter than metal and also has the benefit of being a better thermal insulator, which will help the air in your ducting lose less temperature to the outside environment. Modern plastic dampers are also a lot sturdier than their long ago-made parts. Metal dampers are available in a far wider array of sizes and shapes, so it’s much easier to find one suited to your specific needs in metal rather than plastic.

Common FAQs about Range Hood backdraft

Is a range hood damper necessary?

If the wall or roof cap does not have a damper, it is recommended to use a range hood with a damper (or a model with optional damper capability) in areas of cooler/colder climates (to prevent back drafts) and in warm climates (to prevent insects from passing down through the venting system).

What is the purpose of a backdraft damper?

A backdraft damper, also known as a gravity damper, is a piece of equipment that allows air to flow through in one direction while preventing air from entering the opposite side, also known as a backdraft. Backdraft dampers assist in the exhaust or intake of heating, ventilation, and air conditioning (HVAC) systems.

What is the range hood damper location?

A range hood damper is situated inside your ductwork. It opens when you turn your range hood on to allow for airflow and closes when you turn your range hood off. This prevents back-drafting and keeps any large debris from getting inside your ductwork or into your range hood or vent hood.

How to install range hood backdraft damper?

- Step 1: Gather Tools and Materials. Backdraft damper.

- Step 2: Prepare the Backdraft Installation.

- Step 3: Measuring and Fitting the Damper.

- Step 4: Install the Damper.

- Step 5: Finalize the Damper Installation.